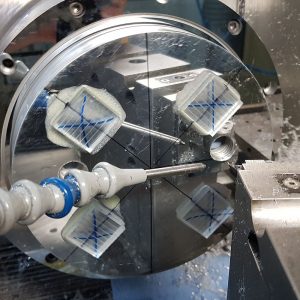

SAVIMEX owns 3 diamond turning machines and offers theirs for ultraprecision components surface finishing.

The cutting tool is a monocrystalline diamond. Its cutting edge can vary in shape and size, depending on the expected result. The machining tools have nanometer-scaled axes control.

Meeting customer expectations

Diamond turning is used for making “free-form” surfaces and diffractive surfaces.

The company is able to implement several diamond turning techniques, depending on custom applications and needs.

Commonly known as Single-Point Diamond Turning (SPDT), these are machining techniques in which the cutting point moves along the part, according to a predefined path.

Several operational configurations are possible.

| Mode | Configuration | Use |

| “Slow-tool” | Rotating part Tool on the Z axis |

spherical, aspheric or “free form” surfaces |

| “Fly-cutting” | Diamond on spindle (fixed Y) Fixed part on X-Z axis |

Flat surfaces |

| “Raster” | Diamond on spindle (Mobile Y) Fixed part on X-Z axis |

“Free form” surfaces |

Industry-leading expertise

Savimex has technical expertise to offer unparalleled precision in terms of form and appearance.

A perfect control of following parameters is required during machining process:

- Machine: intrinsic precision, tool path programming

- Tool: choice, size

- Part: fixing, centering, balancing

- Cutting conditions: rotation and feed rate