SAVIMEX offers injection molding capabilities to manufacture components with a high degree of repeatability and accuracy. This process is a cost-effective way to replicate spherical, aspheric and free-form surfaces and combine them with mounting features.

A thorough understanding of the whole manufacturing process is essential to produce high-quality plastic optics components. Here are the three main areas the company is able to deal with: mold, injection molding machine and used materials.

Mold

SAVIMEX undertakes design and production of each injection mold, in partnership with European molders.

The company has polishing and diamond machining equipment to perform finishing operations of mold inserts with sufficient surface qualities and accuracies for high quality optical components manufacturing.

The metrology laboratory allows very high-performance measurements (nanometric scale).

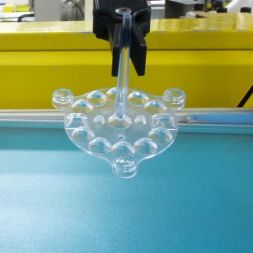

Depending on final component size, multicavity molds can also be realized, which leads to economy scale and higher throughput.

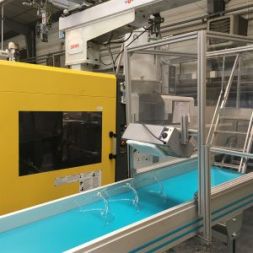

Molding machine

SAVIMEX owns many up-to-date electric injection molding machines, strongly suitable for high-precision optical components manufacturing.

Both pressure and temperature inside the cavity are controlled during injection cycle.

The company implements several injection techniques (injection/compression, hot/cold) for geometrical accuracies improvement.

Wide range of materials

SAVIMEX uses following thermoplastics: PMMA, polycarbonate, cyclic-olefin polymers, silicon or Ultem. They are chosen by Engineers during optical conception phase to perfectly fit environmental and operating conditions.

This selection is made regarding several properties :